Rapid Prototyping

FDM

Fused Disposition Modeling – Produces Functional & Durable Models from CAD

Stratasys FDM 400mc

- Builds up to 16″ x 14″ x 16″ (larger pieces may be made in sections and bonded together)

- Produces parts directly from CAD data

- FDM is an additive fabrication technology (AFT), not subtractive

- Dimensionally accurate to 0.002″ – 0.005″ depending on the tips/slice and material

- Adjustable tip sizes and layer thickness

- Materials available:

- Polycarbonate (black)

- PC (white)

- PPSF (tan)

- ABS-M301 (ivory)

- Example of parts that can be made:

- Engine blocks

- Cylinder heads

- Bedplates

- PTUs

- RDUs

Specialty Fabrication and Low Volume Builds

Specialty Fabrication

McLaren Performance Technologies offers specialized services for:

- Short-run production

- Engine instrumentation

- Cylinder block and head machining for thermocouples

- Prototype intake manifolds

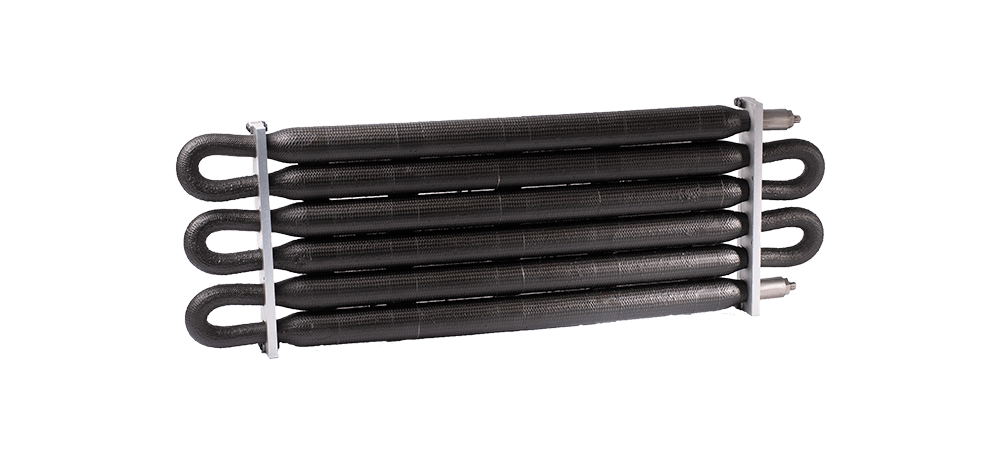

- Prototype oil pan fabrication

- Modifying engine components

- Test, tool, and build fixtures

- Exhaust prototype

- Total vehicle integration for powertrain assemblies

- Cutaway engine and differential displays

- Custom fabrication

- Welding (tig/mig) steel, aluminium, stainless, and alloys

Capabilities:

- FADAL VMC 4 axis

- 6030

- 3016L

- FADAL HL-35CNC Lathe

- HASS VF 3 VMC 3 axis 40″ x 20″ x 22″

- Okamoto 12″ x 22″ auto surface grinder

- Chevalier 8″ x 18″ surface grinder

- (4) Bridgeport mills

- Sharp CNC Mill

- (2) Victor 16″ – 40″ engine lathes

- Hughes tube bender

- Hydraulic-Mechanical horizontal saw

- Pacific Hydraulic Press

- (2) Roper Whitney Hydraulic Sheer

- Kidder Sheer

- Grinders

- Wilson Rockwell hardness tester

- Welders and wire feed system

- Thermo Arc Plasma cutter

Low-Volume Builds

McLaren Performance Technologies has the ability to provide one-of-a-kind or low-volume prototype build activities practicing OEM IATF 16949 and ISO 9001 quality requirements to ensure high integrity quality builds.

Security & Confidentiality

McLaren offers no-view enclosed work areas with secure entry providing maximum confidentiality and discretion for prototype builds for our customers. Inventory is stored securely prior to build requirements.

Technical Expertise

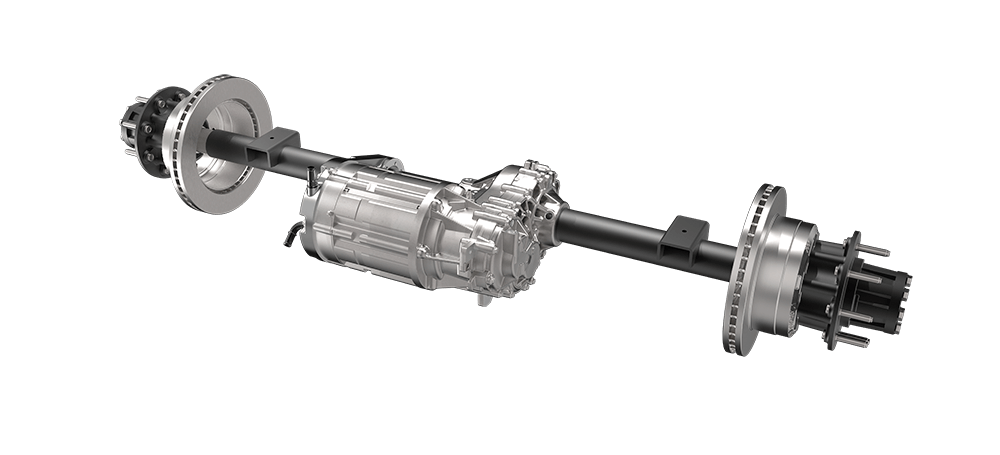

McLaren specializes in creating prototypes for gearbox products and engines as well as many other highly engineered complex assemblies. Experienced project managers and engineers support each build to provide accurate reporting and technical support.

Build Capabilities

- Vehicle Hoists

- (1) 4-post hoist 12,000 lb cap with wheel alignment

- (2) 2-post hoists 9,000 lb cap

- Engine Shop

- Full teardown assembly area

- Rod hone

- Rod heater

- Pin press

- Rod & cap grinder

- CK21 cylinder hone

- CH100 line hone

- Block washer

- RMC 12VB surface with Windfield fixture

- Bayco oven with 4+ block capacity

- Ultrasonic parts washer

- Superflo 1020 flow bench

- Cam Pro Cam Doctor

- Sonic tester